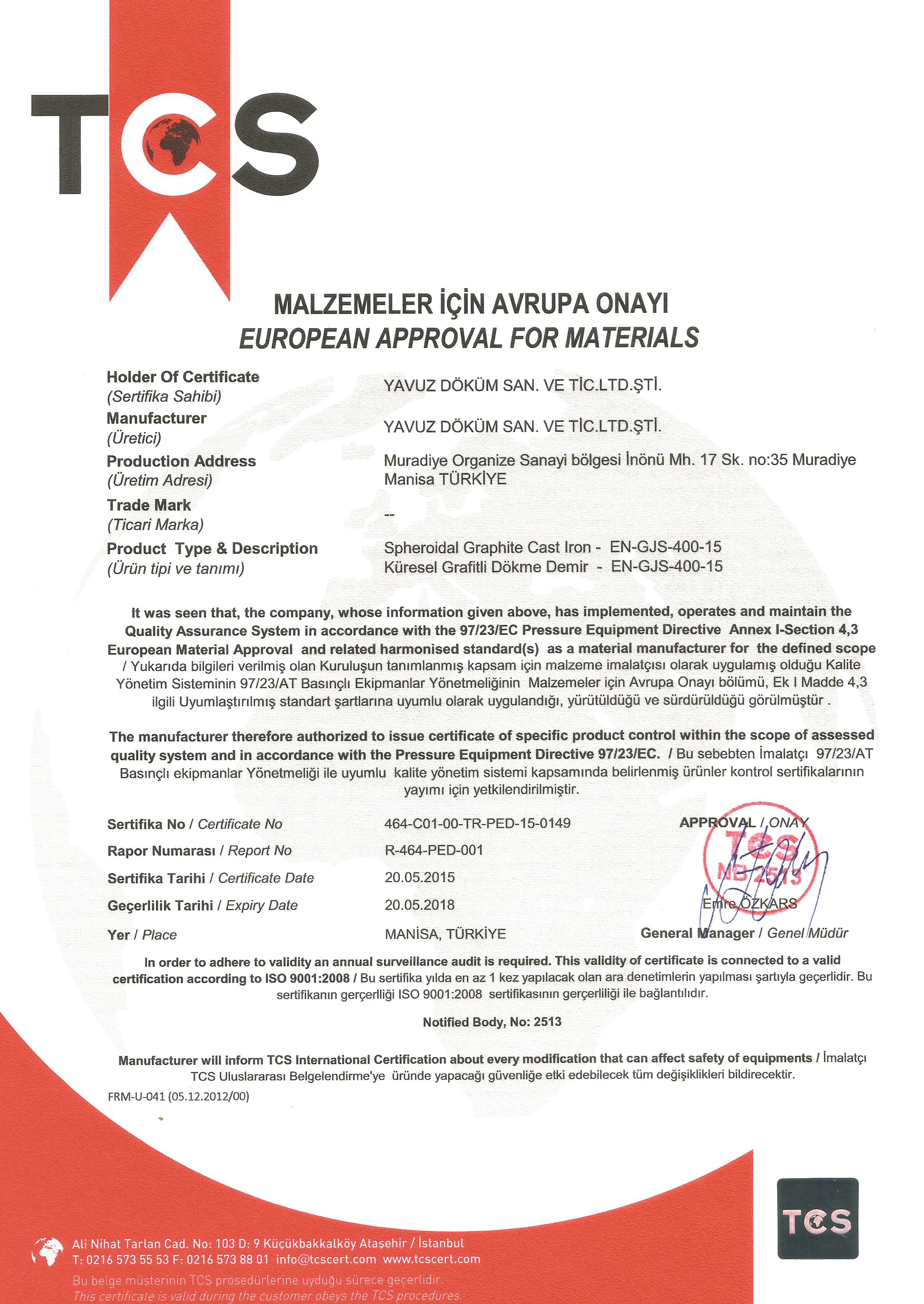

Quality Assurance and The Laboratory

Depending on the principles of ISO 9001:2008 Quality Management System, in accordance with National and International standards, customer requests, would help to meet in full and on time, inspection, auditing, and reporting to, a competent carried out by the quality Assurance team.

- With the OBLF Brand spectrometer device in our laboratory, each alloy is controlled from the smelting furnace, and added vaccination required after the application process, the final sample for analysis from each pot by taking the final inspection is made and recorded and archived.

- After casting material being constant hardness measured with compressive force up to 3000 Kg, Ø10, Ø5 and Ø2.5 mm balled Computer-controlled Brinell hardness tester. Hardness results recorded with graphical reports are archived.

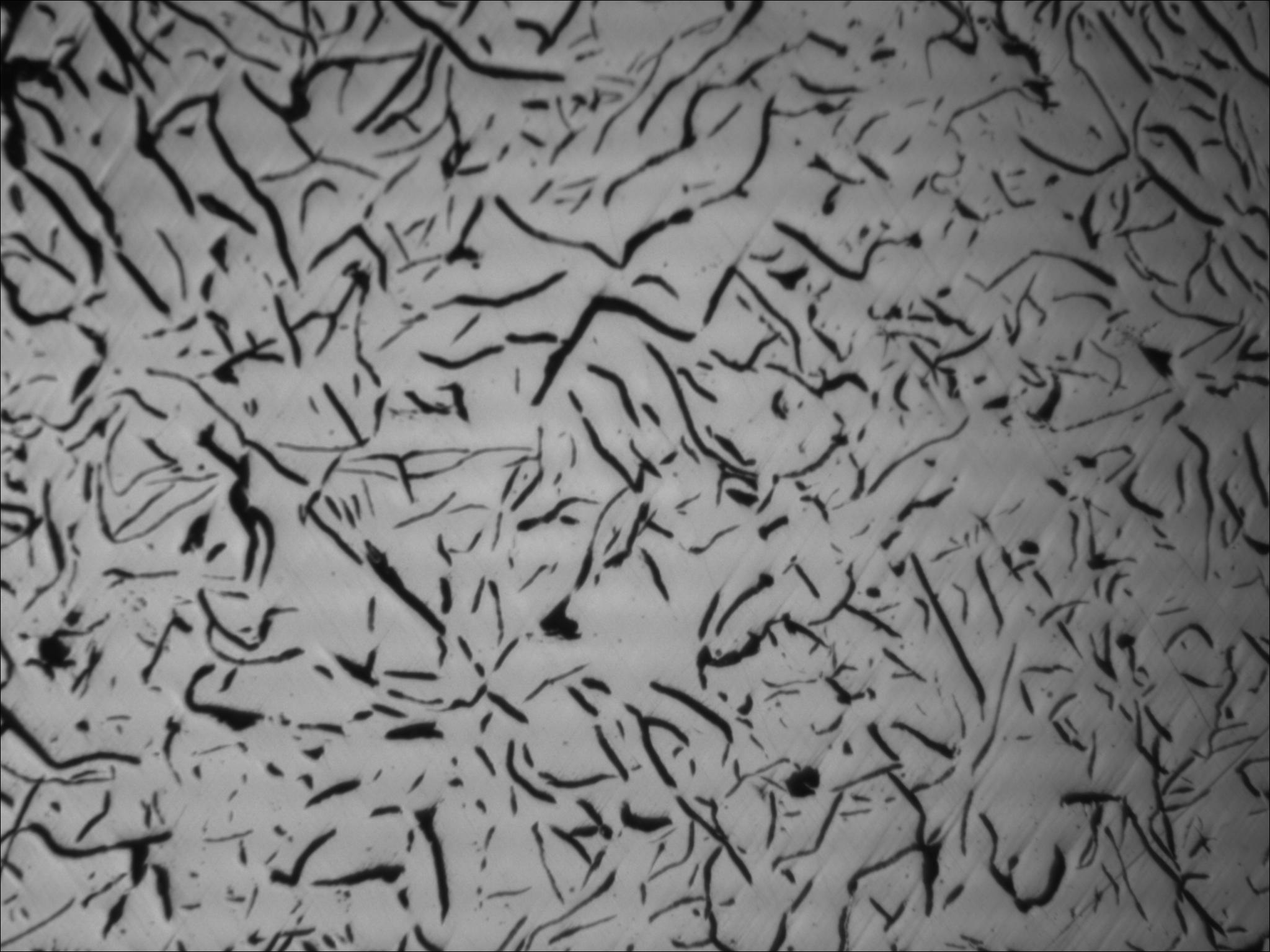

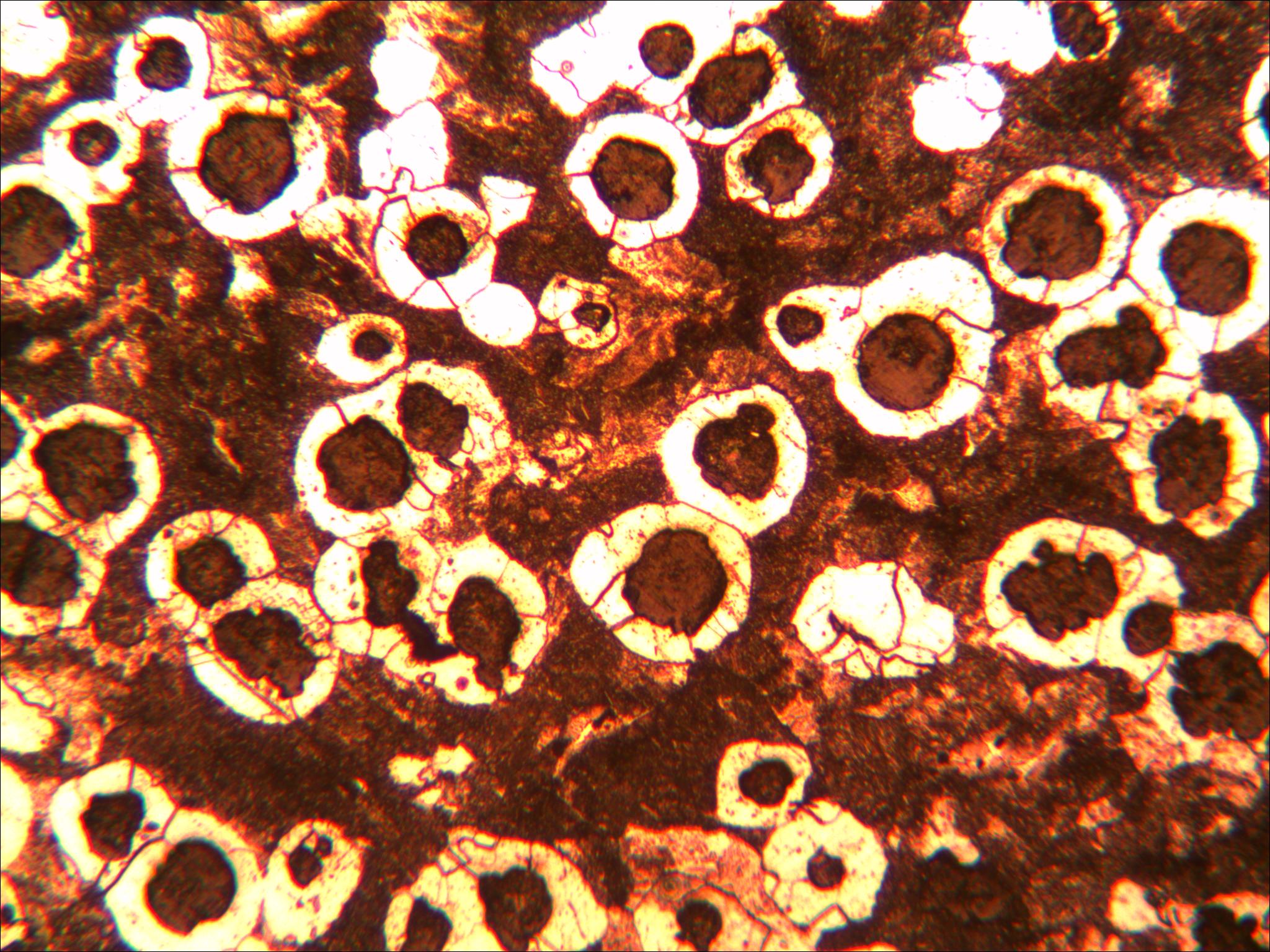

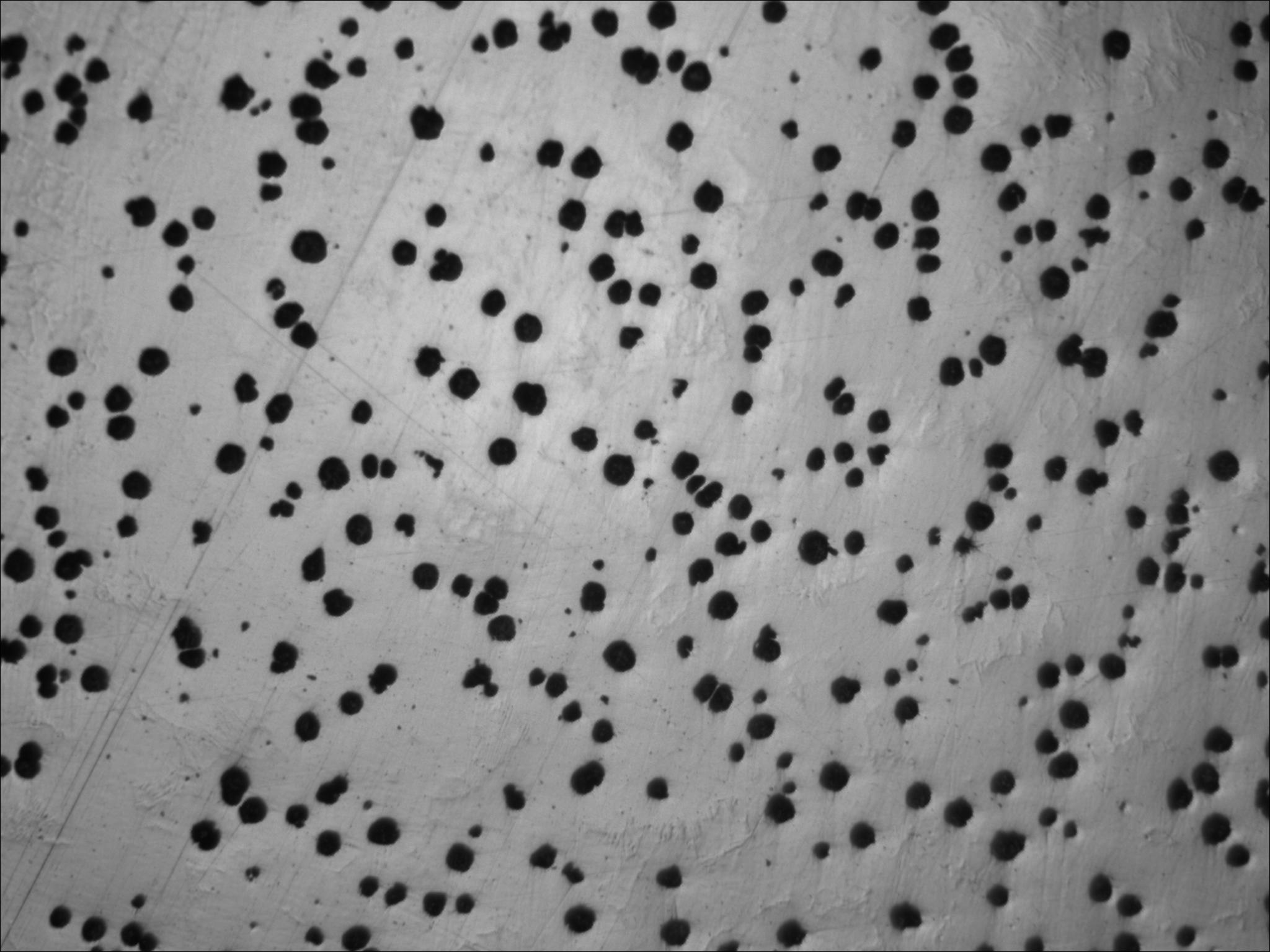

- Casting process takes place after casting method and determined the droplet microstructure control samples taken from products in sample preparation equipment for the control of internal structure are prepared Metal microscopic examination. Taking photographs of each sample examined and the examination results are recorded and archived.

- According to national and international standards was prepared and poured into test bars with Tensile Tester with a capacity of 30 tons, again tested in the manner specified in the standards are archived results.

All the results of the test data obtained from the Material brought together in a Material Control Report are delivered to customers during the transportation of the products.