Our Production Techniques

- Machine Moulding Line

Our enterprise has a 750x550x200 mm PLC-controlled hydraulic system with Max pressure of 200 Bar and a Semi-Automatic Molding Machine with 40 Pieces/Hour mold-capacities. Each has 4 pieces of the line to Cast moulding with a capacity of 21 Degrees and a total of 120 degrees. Manufacturing in the mold products in every shifts average 250 degrees cored and, 300 degrees coreless.

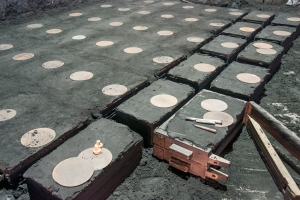

- Resin Molding Line

Resin molding method of manufacturing can be made with Resin sand mixers by a single piece of 4,000 Kg of Ductile Iron 3000x4000x1200 mm or 6,000 Kg of Cast Iron with 10 Tons/Hour capacity. High-tonnage molding of products is carried out smoothly with high quality by our own well trained qualified personnel in this branch for over 10 years. All other branches as well as in resin molding moulding quality consumables are used. Patterns are painted with paint machine by washing procedure.

- Synthetic Sand Moulding Line

In line with customer demand, the smaller size and weight of affairs in hand molding method is also used in the manufacture. With hand molding masters trained in the areas of manufacturing, as well as other molding lines, quality control at each stage of audit and supervision are conducted.

Cold Box, Carbon Dioxide gas and Resin core manufacturing are done with Sand mixer which has 6 Tons/Hour capacity. Depending on the size of cores is prepared by hand with a capacity of 8 liters core machine. Resin sand being used for Heavy-tonnaged core, and all the cores paint with stained areas of moulding with best-in-class quality refractory.

Melting is made with 2 Tons/Hour capacity of 2 (800 Kw/900 V ) Induction furnaces. Monthly 350 Tons of metal melting and casting capacity in one piece up to 6 Tons of Cast Iron, 4 Tons of Ductile Iron parts are manufactured.

The production of completed casting parts cleaned deburring process for preparation with the 3 turbined PLC-controlled fully automatic sandblasting machine has solid 2 Tons/Hour and 8 Tons/Hour capacity.

Sandblasting made parts, according to their deburring and cleaning equipment are cleaned with the appropriate counter and is ready for shipment.

Sandblasting made parts, according to their deburring and cleaning equipment are cleaned with the appropriate counter and is ready for shipment.

In line with customer demand thermal processing will be subject to pieces, Max. 10 Tons of Heating capacity, programmable Heat treatment furnaces in the suppression of Voltage, Normalization, annealing and Smoothing.

Model and core boxes that submitted for manufacturing to us are kept in appropriate storage areas before and after the production. They are kept in a manner protected shelves from adverse weather and ambient conditions when not in use.